Electrical Power Management Solutions Guide

POF uses in Uninterrupted Power Supply (UPS), Battery Management and EV Charging Stations

Why use Plastic Optic Fiber around batteries and in a UPS or EV charging station ?

Battery banks, UPS devices and EV charging stations all have the same common operating and maintenance risks.

The primary operating risk is the generation of significant EMI from the large changes of current in short time scales (large dI/dt), which can cause spikes on digital circuitry damaging controllers and bringing drive systems to malfunction resulting in current surges producing heat damage, short circuits and also causing fire damage with resulting equipment and possibly personal injury.

The primary maintenance risk is of a short circuit generating a current surge and resulting in personal injury, fire and equipment damage.

Plastic Optic Fiber is, 100% plastic and consequently does not conduct electricity and cannot therefore cause a short circuit.

Plastic Optic Fiber is 100% immune from electrical or magnetic pickup hence it will isolate command and control digital electronics from the power switching electronics' interference usually located in UPS or EV charging stations. Equally POF can provide high speed data connections between devices without the risk of carrying unwanted EMI/RF interference from one unit to another.

UPS and Battery Management

UPS and Battery Management systems typically use CAN bus to monitor individual power packs. While CAN is very useful for the sensor interface and measurement, the wired solution is not ideal for power-pack to power pack inter-connector or for overall digital management of the system.

A wired connection can,

- Transfer power spikes due to over-current conditions

- Transfer RF/ EMI disturbances from the power pack switching back to the controller

- Transfer surge current in the case of accidental short-circuits of the power and data lines

A Plastic Optic Fiber Link will,

- Provide complete isolation from power spikes

- Provide complete isolation from RF/ EMI disturbances

- Eliminate the risk of short circuits between power and data sources

By using a CAN-to-RS232 converter (e.g. MAX232) and adding Firecomms DC-50 MBd transceivers you can connect the local CAN network of each cell or battery pack or individual UPS to the overall control network via an Optical RS-232 / RS-485 link over plastic optic fiber.

This isolated the control network from each unit/ cell/ pack providing 100% protection from any contagion when an issue arises with an individual unit.

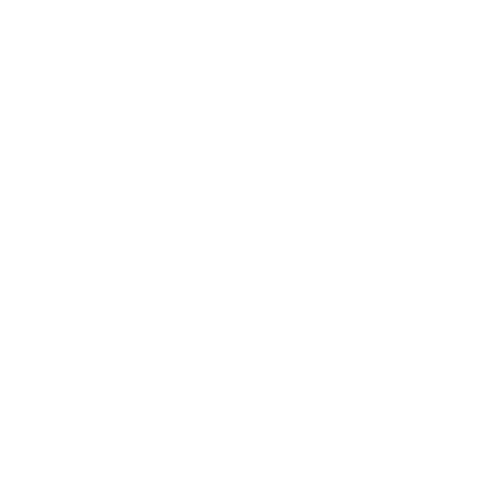

Electric Vehicle Charging Infrastructure

In an Electric Vehicle station plastic optic fiber provides isolation between the Electrical driver PCB and the main control digital electronics.

This provides complete electrical isolation between the electrically noisy current switching of the charging driver and the low power digital electronics of the control unit.

In this case plastic optic fiber is preventing noise from the current switching necessary to deliver fast clean power to the vehicle battery bank from propagation back to the control electronics and eventually causing damage to the operating network. This can be the local controller and or a remote controller. Internally inside the Electric Vehicle unit itself low speed control communication between PCB?s is ideally suited to POF links using Firecomms RedLink® transceivers. The POF links can be field maintained which is one of the biggest benefits of POF compared to glass fiber technology.

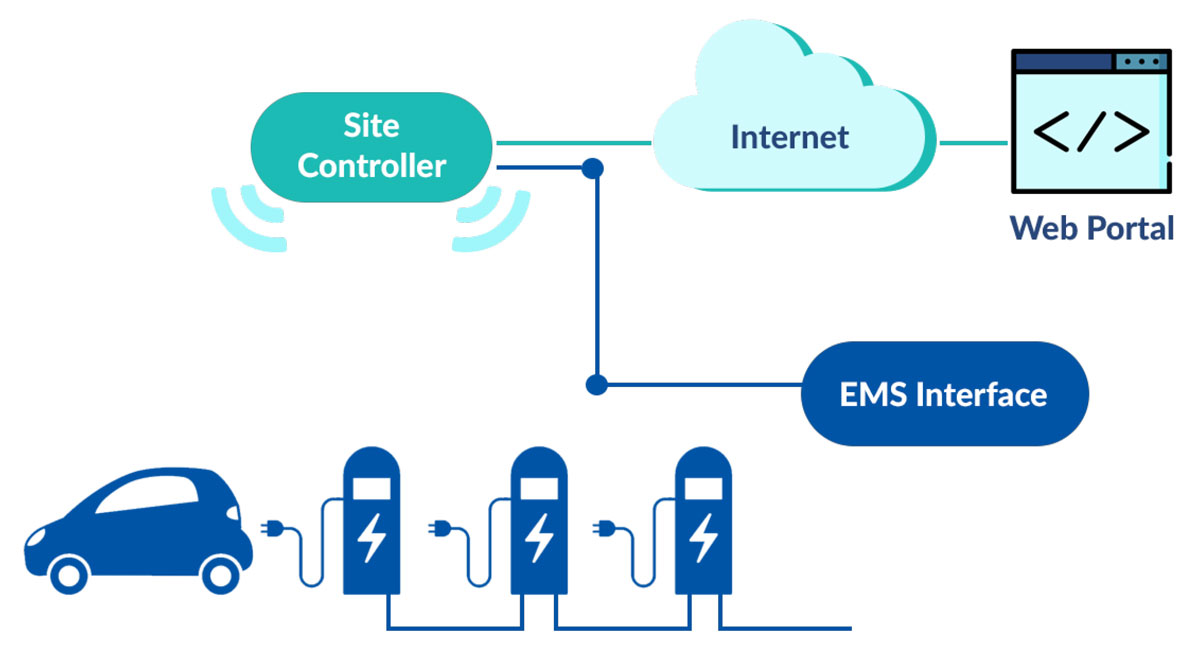

Electric Vehicle Charging

Plastic Optic fiber provides an excellent solution for Electric Vehicle data management.

- The fiber can be co-located with AC power conductors in a composite cable suitable for delivering power and data together with complete isolation of the data from or interference from the power delivery.

- Full Ethernet, EtherCAT or company specific 8B10B data encoded protocols up to 250 Mbps are supported over POF.

- Fast Ethernet links over POF are supported for extreme weather conditions with ambient temperatures of -40°C to +85°C over 80 m in a point to point link.

- By using Firecomms transceivers local Fast Ethernet POF links can be extended to 1 km using standard glass fiber where very long links are required in the infrastructure.

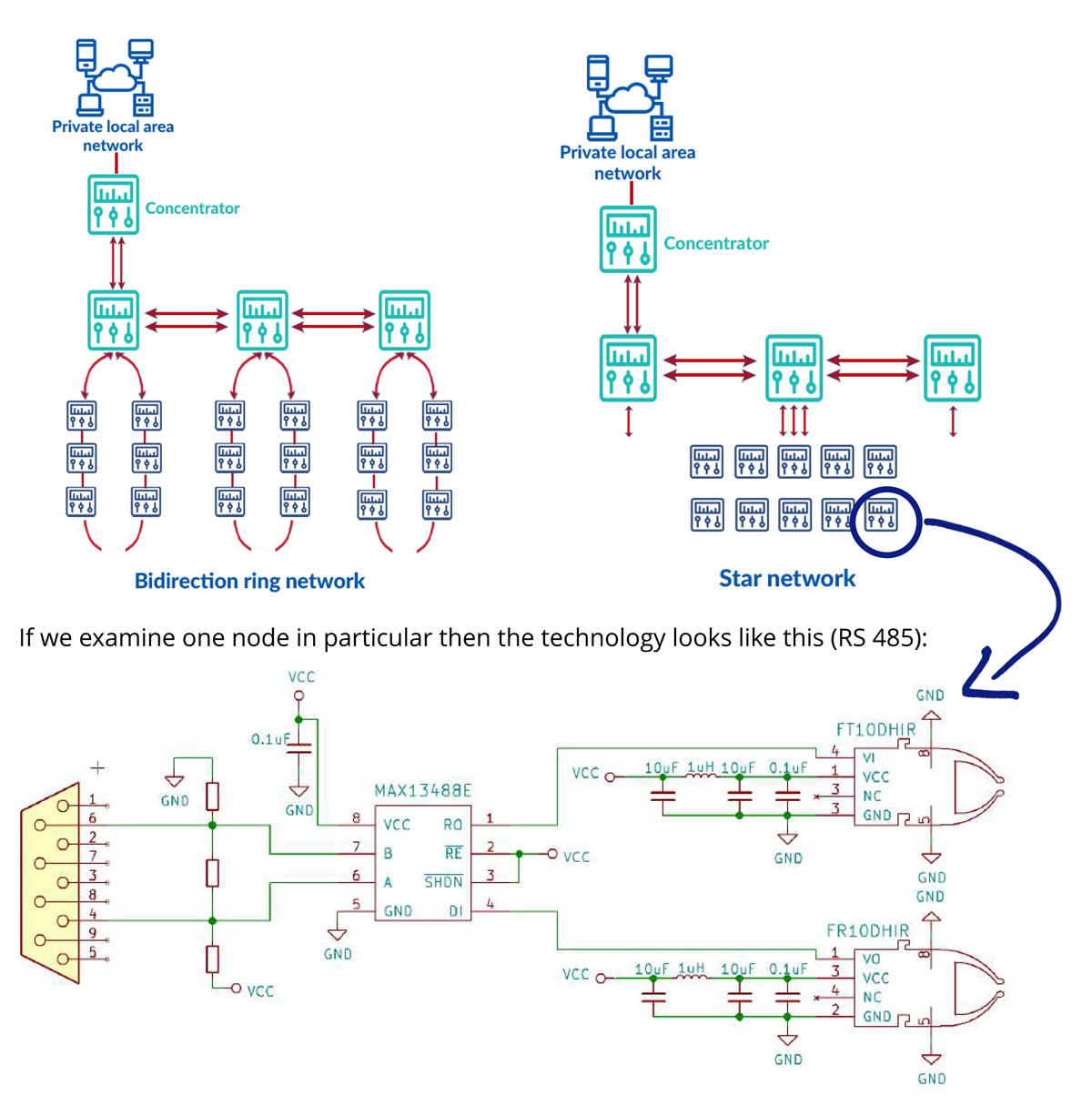

- Installations can be STAR or Daisy Chain or mixed as required by the infrastructure

Power Metering in UPS/Battery Management /EV Stations using CAN, RS232/485 and POF

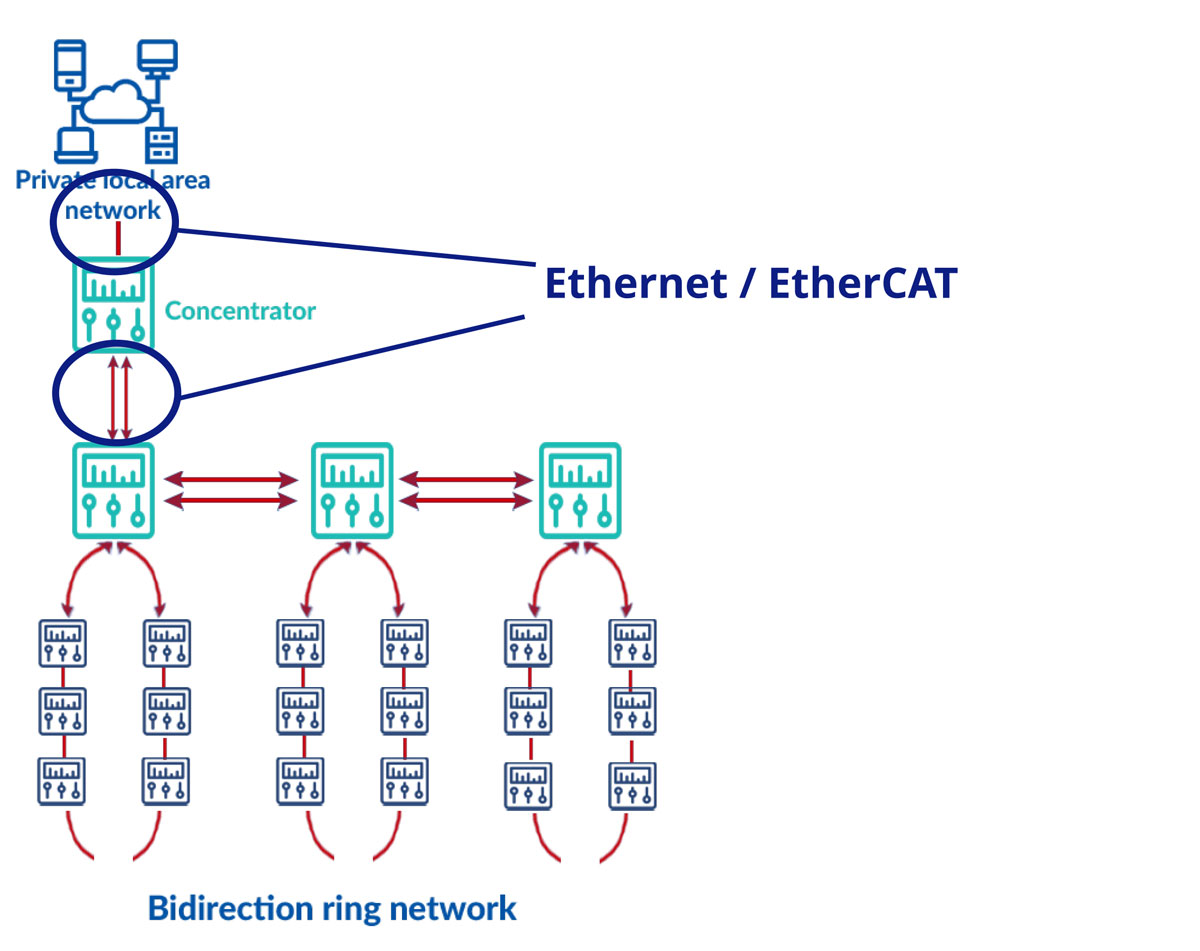

The images below show examples of POF used to link a network of devices measuring power usage, system health, system control etc. The red links represent plastic optic fiber interconnections. The boxes can be UPS units, Battery storage units or EV charging points or combinations of such equipment.

Ethernet / EtherCAT

Plastic Optic Fiber (POF) supports Ethernet as 100Base-FX which is part of the IEEE 802.3 standard

The 100 Mbps Fast Ethernet link enables remote and cloud-based monitoring of equipment including operations, sensors, billing and maintenance. As POF supports fully the IEEE802.3 Physical layer it also supports the EtherCAT bus which runs on layer 7.

The OptoLock® offers simple clean fiber termination that does not require special tools or special training. It can be installed by any technician.